杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

Introduction to Membrane Products and Technologies

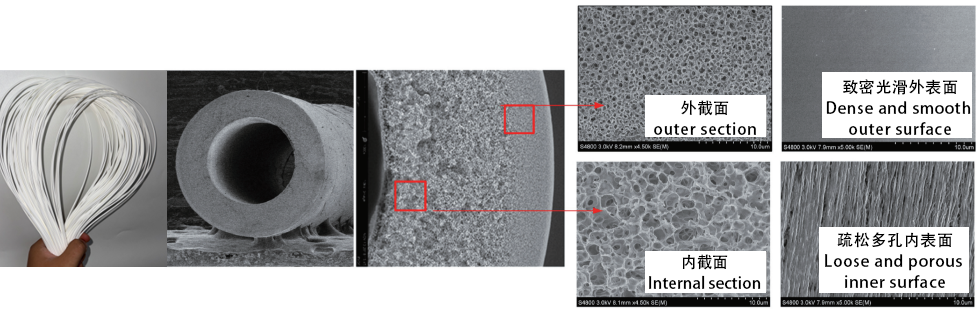

The external pressure type polyvinylidene fluoride alloy film is a new generation of high-performance product successfully launched by Hangzhou Jinlong Membrane Technology Co., Ltd. after years of research and development. The Jinlong alloy membrane product, in response to the urgent needs of the country such as wastewater resource utilization and environmental protection, uses ultra-thin carbon nanosheets with moderate hydrophobicity, super-large two-dimensional planar structure, excellent oxidation resistance and high mechanical strength as additives. During the film formation process, it builds two-dimensional ordered water guiding channels, simultaneously achieving a synergical improvement in water flux, mechanical strength and chemical stability.

The Jinlong alloy film integrates key properties such as high orientation degree, high water flux, high tensile strength, high oxidation resistance, anti-pollution and service stability. Its comprehensive performance indicators exceed those of similar products from developed countries such as the United States, Japan and Singapore.

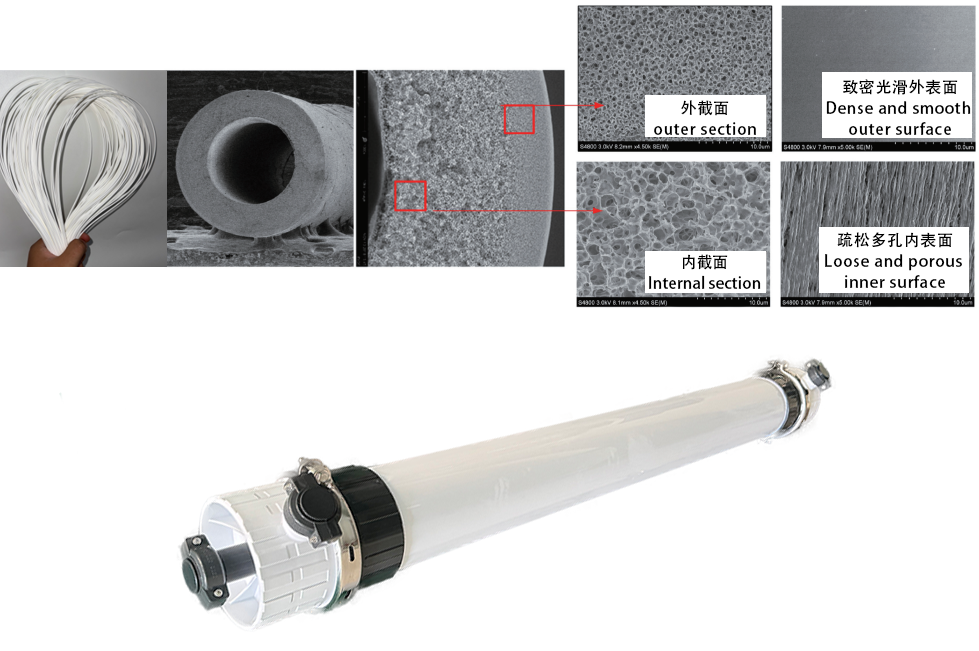

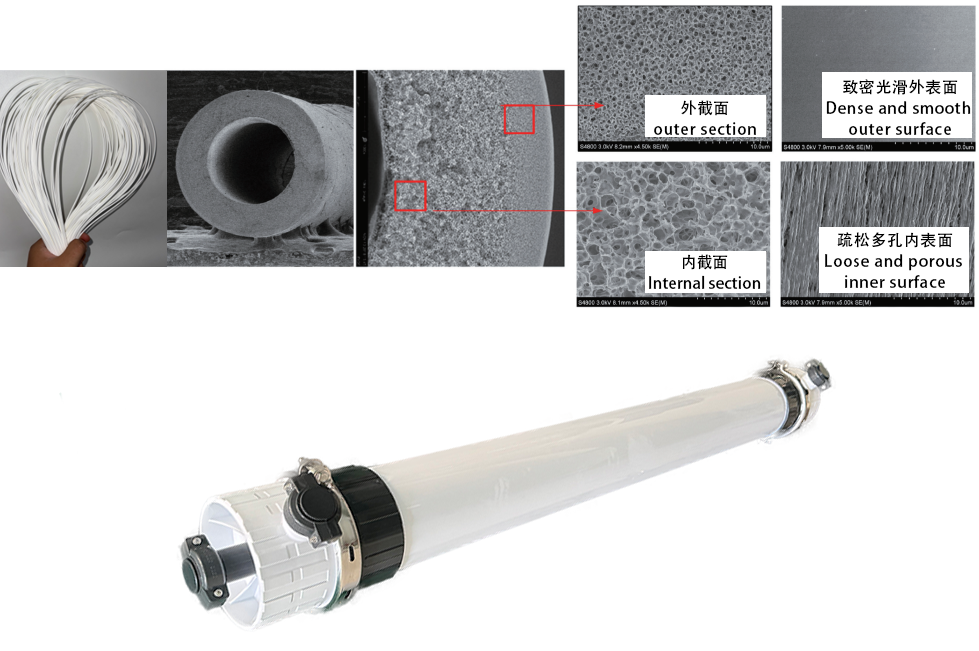

External pressure type sponge cell structure

The Jinlong alloy membrane and polyvinylidene fluoride ultrafiltration membrane present an ordered gradient structure in which the membrane pores gradually increase from the outside to the inside along the radial cross-section. The treate liquid enters from the outside of the hollow fiber membrane and seeps out from the inside of the hollow fiber membrane under pressure drive, effectively overcoming the shortcomings of the conventional external pressure hollow fiber membrane, such as small effective membrane area and insufficient backwashing. Meanwhile, as the separation layer is located inside the membrane structure, it effectively avoids the influence of external conditions during the preparation process, ensuring the uniformity of the membrane filament performance.

Uniform pore size and high-quality water production

The average filtration pore size of the Jinlong alloy membrane and the polyvinylidene fluoride ultrafiltration membrane is approximately 0.03μm, with a uniform pore size distribution, mainly within the range of 0.015 to 0.025μm. It can effectively remove suspended solids, bacteria, viruses, colloids, etc. The turbidity of the produced water is less than 0.1NTU, ensuring excellent effluent quality.

Main technical parameters

Product name | Jinlong Membrane | Jinlong Extreme Films |

Membrane model | PVDF-GO type | PVDF-GH type |

Membrane type | Low-content ultra-thin carbon nanosheet alloy film | High-content ultra-thin carbon nanosheet black gold film |

Membrane material | PVDF + ultra-thin carbon nanosheet alloy | PVDF + ultra-thin carbon nanosheet alloy |

Filtering method | External pressure type | |

Aperture (μm) | <0.03 | |

Molecular weight cutoff (KD) | 67 | |

Inner/Outer diameter (mm) | 0.6/1.1 or 0.7/1.3 | |

Elongation rate (%) | >250 | >300 |

Single filament strength (N) | >4.5 | >5.0 |

Initial pure water flux (L/㎡·h) at 25℃ and 0.1MPa | >600 | >800 |

Maximum residual chlorine concentration of the cleaning agent | 3000 | 4000 |

Bubble point (water/MPa) | >0.4 | |

Maximum inlet water pressure (MPa) | 0.60 | |

Water production turbidity (NTU) | <0.1 | |

Bacterial retention rate (%) | >99.9999 | |

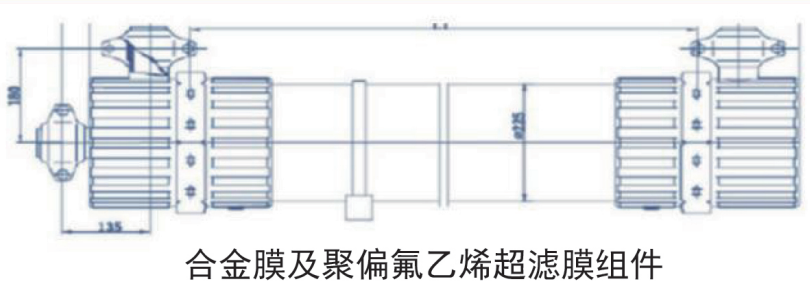

Graphene alloy membrane module | Specification D | Size M | ||||

Component type | 2660 | 2860 | 2880 | 6060A | 8060A | 8080A |

Filtration accuracy (μm) | <0.02 | |||||

Inner and outer diameters of the membrane (mm) | 0.6/1.1 or 0.7/1.3 | |||||

Effective membrane area | 33 | 55 | 77 | 35 | 55 | 75 |

Component dimensions | Φ165x1860 | Φ225x1860 | Φ225x2360 | Φ160x1736 | Φ225x1757 | Φ225x2257 |

Maximum operating pressure (bar) | 6.0 | |||||

Operating flux (L/m²·h) | 40~120 | |||||

Water production turbidity (NTU) | ≤0.1 | |||||

SDI | ≤3 | |||||