杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

EHBR water body restoration aeration membrane technology

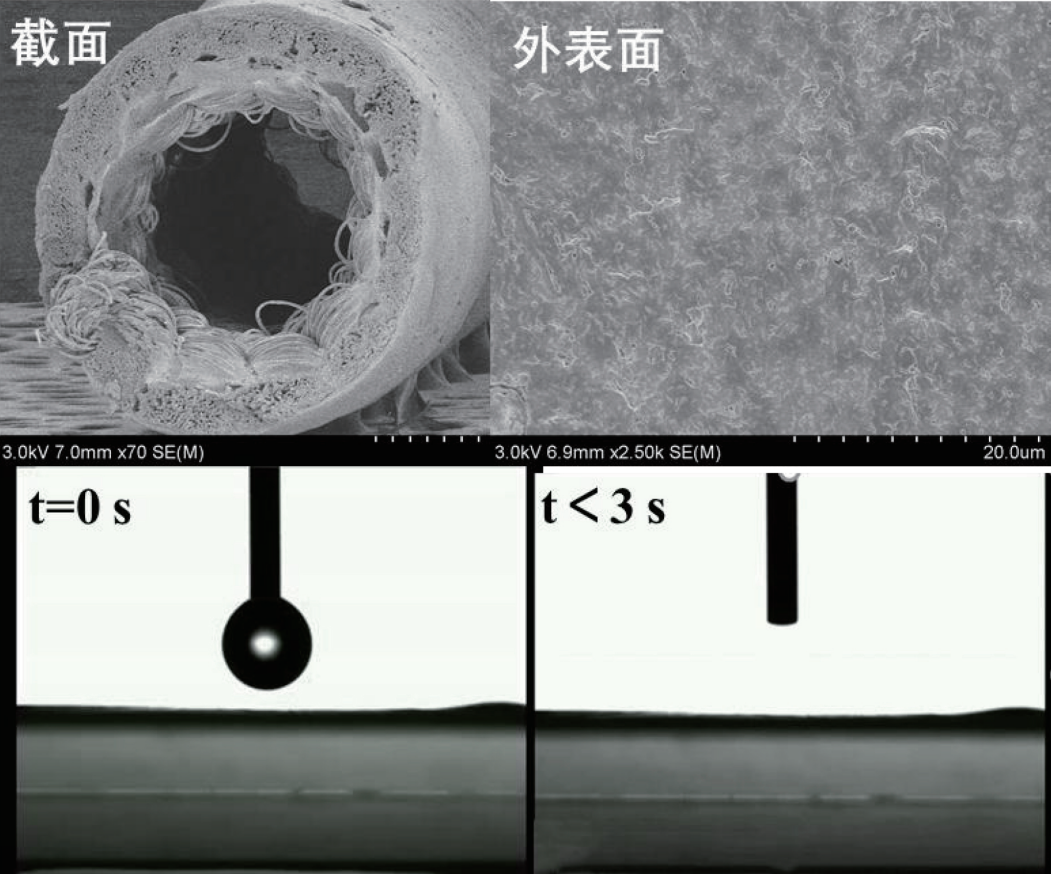

The ENHANCED HYBRID BIOFILM REACTOR (EHBR) technology is a new type of water body ecological restoration and treatment technology with enhanced coupling of micro-nano porous gas separation membranes and biofilms. While air passes through the micro-nano pores and high porosity EHBR membrane in the form of water vapor atomization to efficiently aerate and supply oxygen to the polluted water body, the original ecological microorganisms in the water body gather, attach, expand and reproduce on the surface of the EHBR membrane with excellent hydrophilicity and biofriendliness, and simultaneously adsorb and decompose organic matter and ammonia nitrogen and other pollutants in the water, thereby achieving the effect of ecological purification of the water body.

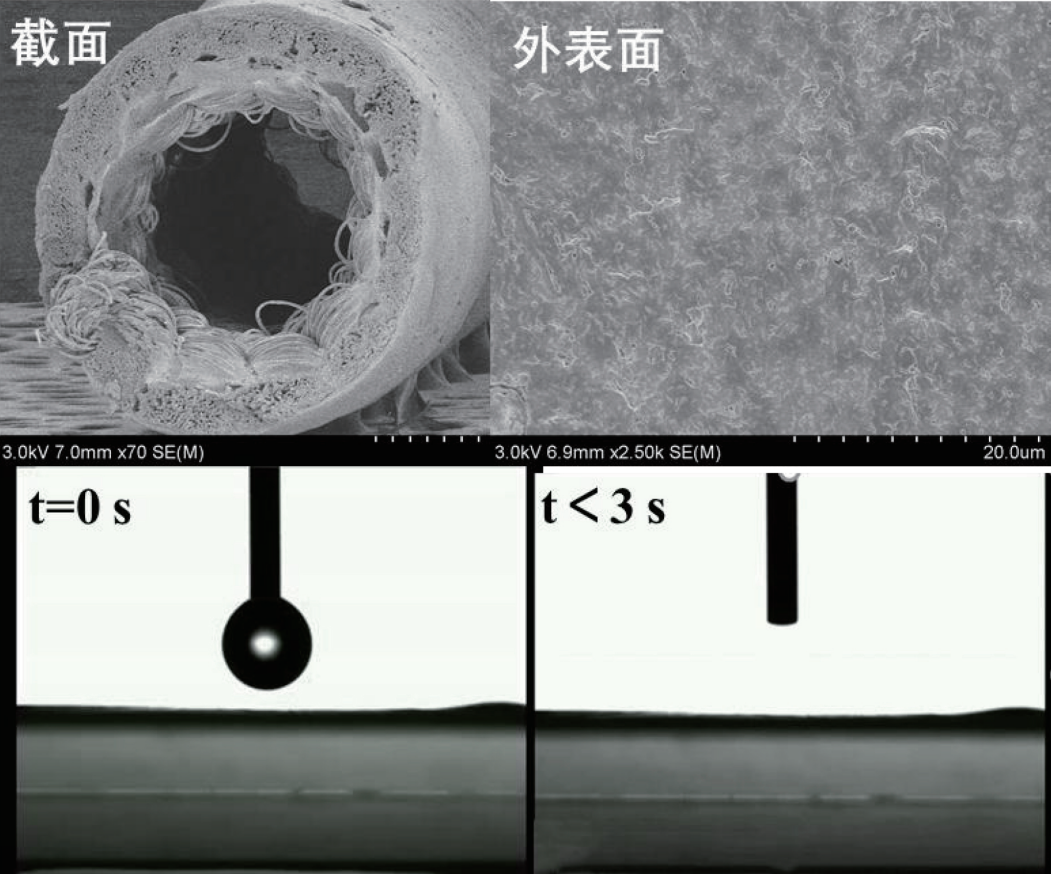

Ordered gradient micro-nano pore technology: nano-physicochemical oxygenation

By designing a high-porosity, outward-dense and inward-loose gradient ordered sponge-like pore structure, the resistance to filtration and mass transfer is reduced, achieving ultra-low pressure micro-nano bubble water vapor atomization aeration for efficient water oxygenation.

Plasma strong bonding technology: Ultra-high peel strength

By adopting surface plasma treatment technology and surface and interface crosslinking agent bonding synergistic technology, alloy membrane materials with ultra-high peel strength are obtained, significantly enhancing the peel performance of long-term aeration membrane materials and extending the service life of membrane products.

Asymmetric technology with internal repellency and external affinity: high strength and easy biofilm formation

The mechanical strength of the membrane is enhanced by adopting the hydrophobic braided tube lining alloy reinforcement technology. By adopting surface hydrophilic modification technology, bionic friendly surface interfaces are created to achieve easy biofilm formation, proliferation of microorganisms and efficient ecological restoration of sewage.

Main technical parameters of EHBR

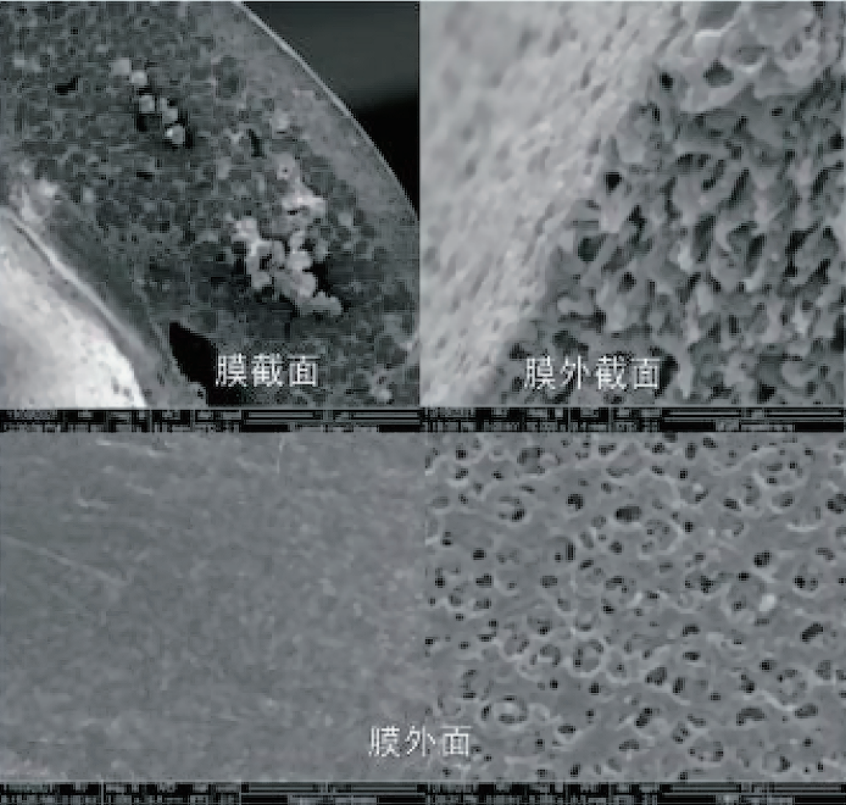

Name | Jinlong Membrane - EHBR | SEM photo of EHBR aeration membrane |

Membrane material | Enhanced composite membrane material |

|

Membrane pore size (μm) | <0.1 | |

Inner/outer diameter of membrane filaments (mm) | 0.4/0.85 | |

Membrane filament tensile breaking strength (N) | >150 | |

Membrane filament peeling strength (N/cm) | >30 | |

Air permeability (L/㎡·h) | >35 | |

Working air pressure (bar) | 0.1~0.3 | |

Applicable water temperature (℃) | -10~50 | |

Applicable water body pH | 2~12 | |

Applicable water salinity (mg/L) | <10000 | |

Membrane module housing material | UPVC | |

Membrane module interface dimensions | Standard tube size: φ25x4mm | |

Typical lifespan | Over 5 years |

Application forms of EHBR aeration membrane

Curtain membrane module

It is suitable for the characteristics of different river flow patterns and has excellent resistance to water flow impact, in-situ microbial biofilm formation ability and efficient pollutant degradation ability.

Modular mold base

It is applied to both flowing and stationary river water bodies, lakes and small and micro water bodies. According to the structural characteristics of water bodies, it can be combined into various forms of membrane frame structures. It features a simple structure, rapid improvement of water quality, low cost and simple operation and management, which is conducive to the construction of water body ecosystems.

Membrane curtain floating island

The combination of EHBR membranes and ecological floating beds organically integrates ecological landscapes with efficient ecological restoration, making it suitable for the purification and landscape creation of still or slow-flowing water bodies. It features energy conservation, mobility, high efficiency, rapid water quality improvement, and significant landscape ecological effects.