杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

杭州津陇膜材料科技有限公司

Hangzhou Jinlong Membrane Material Technology Co., Ltd.

Gas separation membrane technology, as a novel separation technology, boasts advantages such as high efficiency and energy saving, compact equipment, simple operation, environmental friendliness, and ease of integration and coupling with other technologies. It is hailed as the third-generation gas separation technology with the most promising development and application prospects, following "cryogenic separation" and "pressure swing adsorption separation". The core of membrane technology lies in the membrane, and the currently industrialized membranes are primarily polymer membranes. However, as the application of membrane technology becomes increasingly widespread, the market's demands for membrane material performance are escalating. Traditional polymer membranes, due to prevalent issues such as low gas permeability coefficient, poor thermal and chemical stability, and susceptibility to plasticization under high pressure, are gradually unable to meet market demands. Therefore, our company's research and development of novel high-performance polyimide gas separation membranes is crucial for the development and large-scale application of membrane technology.

Polyimide (PI), a class of high-performance specialty engineering plastics, exhibits excellent high-temperature resistance, mechanical strength, chemical stability, and electrical insulation properties. Its molecular backbone contains a stable imide ring structure (-CO-N-CO-), endowing the material with a very high thermal decomposition temperature (typically exceeding 500°C) and a long-term use temperature range from -269°C to above 260°C. Additionally, it possesses an extremely low thermal expansion coefficient and excellent radiation resistance.

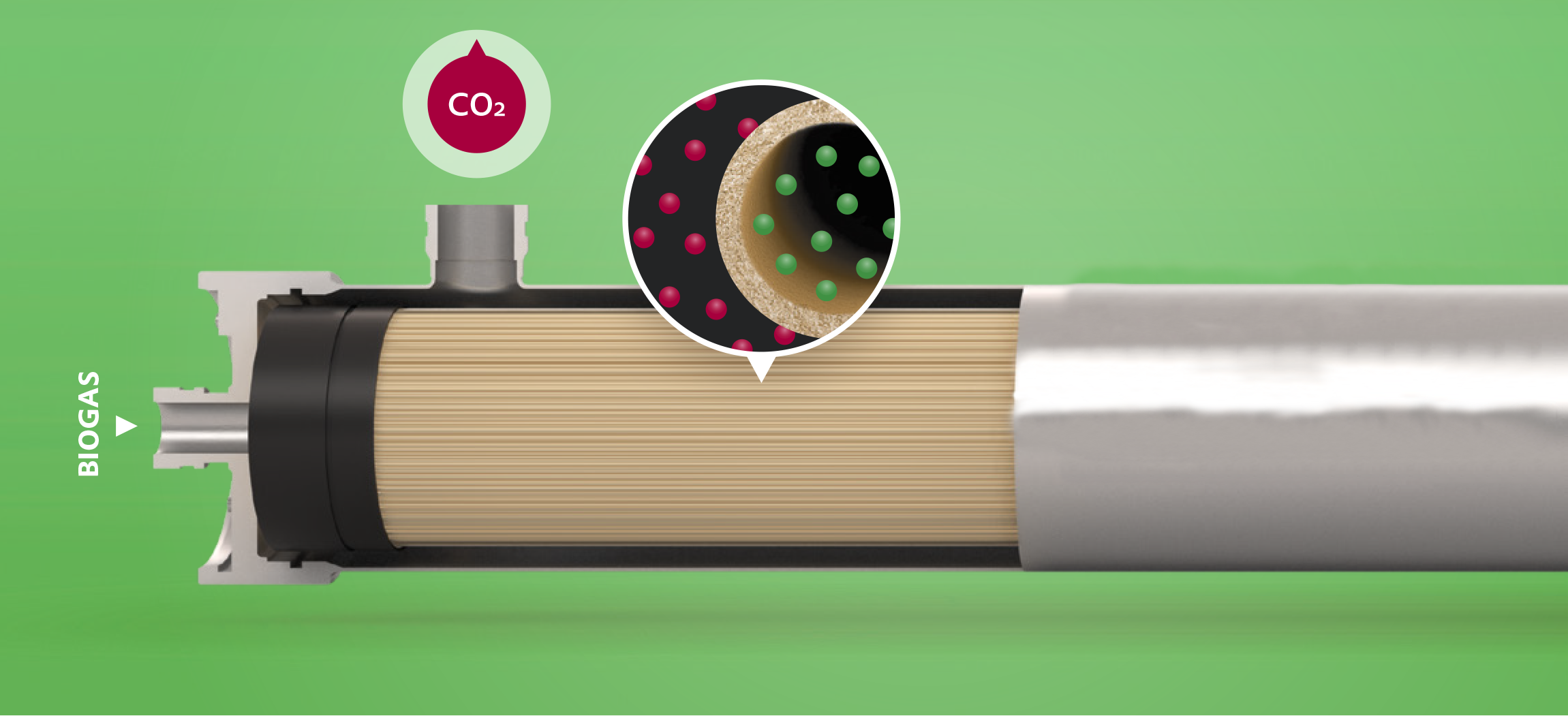

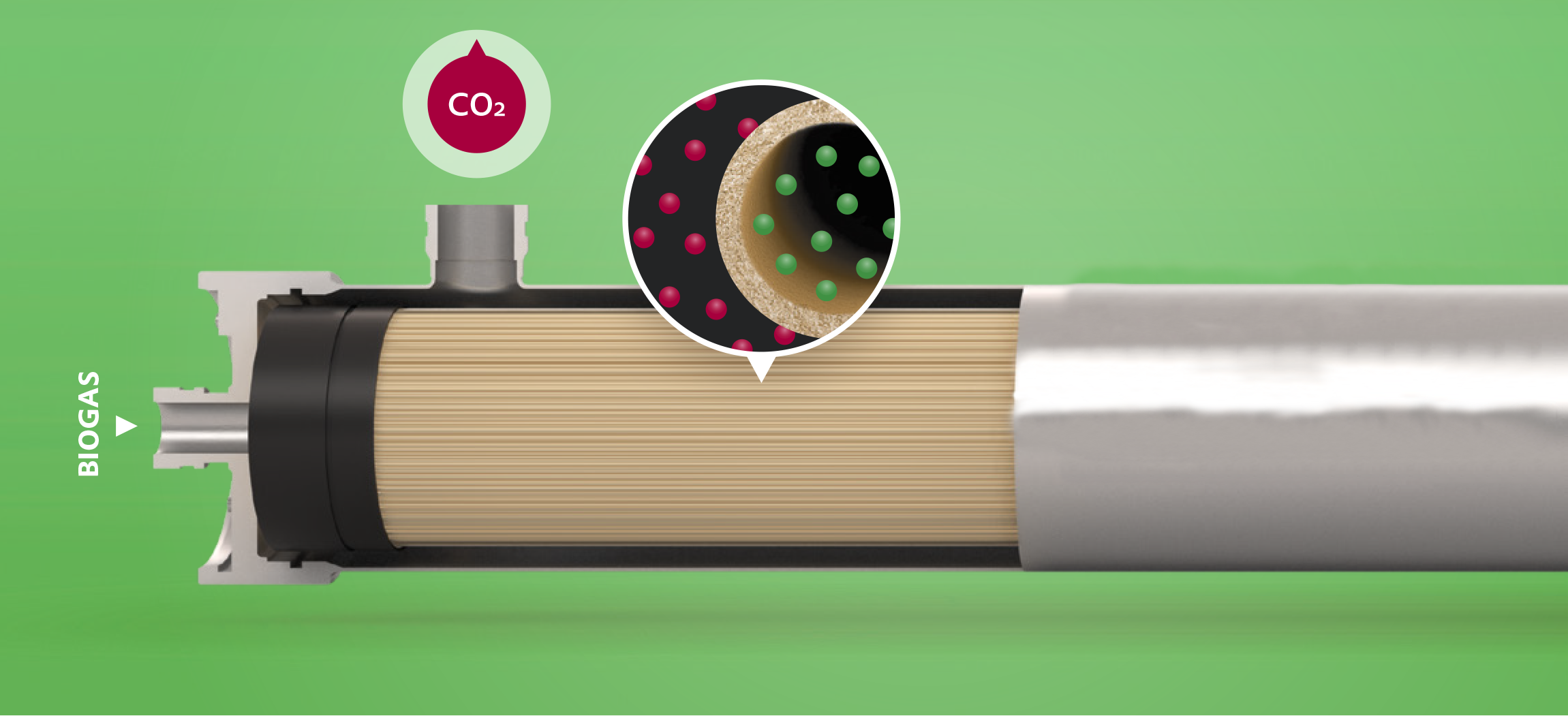

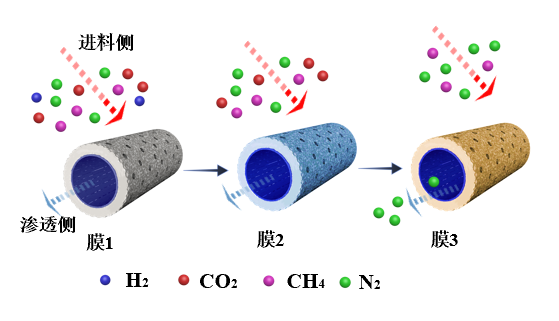

Various important chemical production processes, such as enriching oxygen or nitrogen from air, purifying and recycling hydrogen, capturing carbon dioxide from flue gas, purifying natural gas or biogas, preparing rare gases, recovering organic vapors, separating olefins and alkanes in petrochemical production, and adjusting synthesis gas, all rely on gas separation technology. For instance, the capture and separation of CO2 (including CO2/CH4, CO2/N2, and H2/CO2 separation) holds significant importance in reducing greenhouse gas emissions, mitigating the current energy and environmental crisis, and promoting sustainable economic development. Currently, solvent absorption, solid adsorption, and cryogenic distillation are primarily employed in industry. However, these separation technologies generally suffer from issues such as high energy consumption, elevated separation costs, and environmental pollution caused by adsorbent regeneration. Therefore, developing innovative, energy-efficient, and environmentally friendly gas separation technologies is crucial for achieving strategic goals like green, environmentally friendly, and sustainable economic development. Membrane gas separation technology, as a novel and advanced method of gas separation, has garnered widespread attention in recent years, as illustrated below. The principle behind gas separation membrane technology lies in utilizing the varying permeabilities of different gases through specific membranes. Driven by the pressure difference between the two sides of the membrane, gases with a faster permeation rate are enriched on the permeate side, while those with a slower rate are enriched on the feed side, thus achieving separation. Compared to traditional separation methods, gas separation membrane technology offers numerous advantages, including no phase change, low energy consumption, high separation efficiency, high equipment integration, small footprint, simple and continuous operation, and environmental friendliness. It is hailed as the third-generation novel gas separation technology with the most promising development and application prospects, following "cryogenic separation" and "pressure swing adsorption separation".

China has made significant breakthroughs in the use of membrane separation technology in petrochemical product separation and natural gas purification, bringing good economic and social benefits. As an efficient, energy-saving, and environmentally friendly "green" separation technology, gas separation membrane technology has demonstrated great potential for applications in petrochemical, smelting, food, pharmaceutical, and other fields. However, to date, the market share of membrane gas separation technology remains relatively small, mainly due to the generally low gas permeability coefficient and separation selectivity of membrane materials, which are the core of membrane technology, as well as the mutual constraints between them, poor long-term operational performance, and issues such as plasticization or physical aging, thus limiting the large-scale application of membrane separation technology in industrial production.

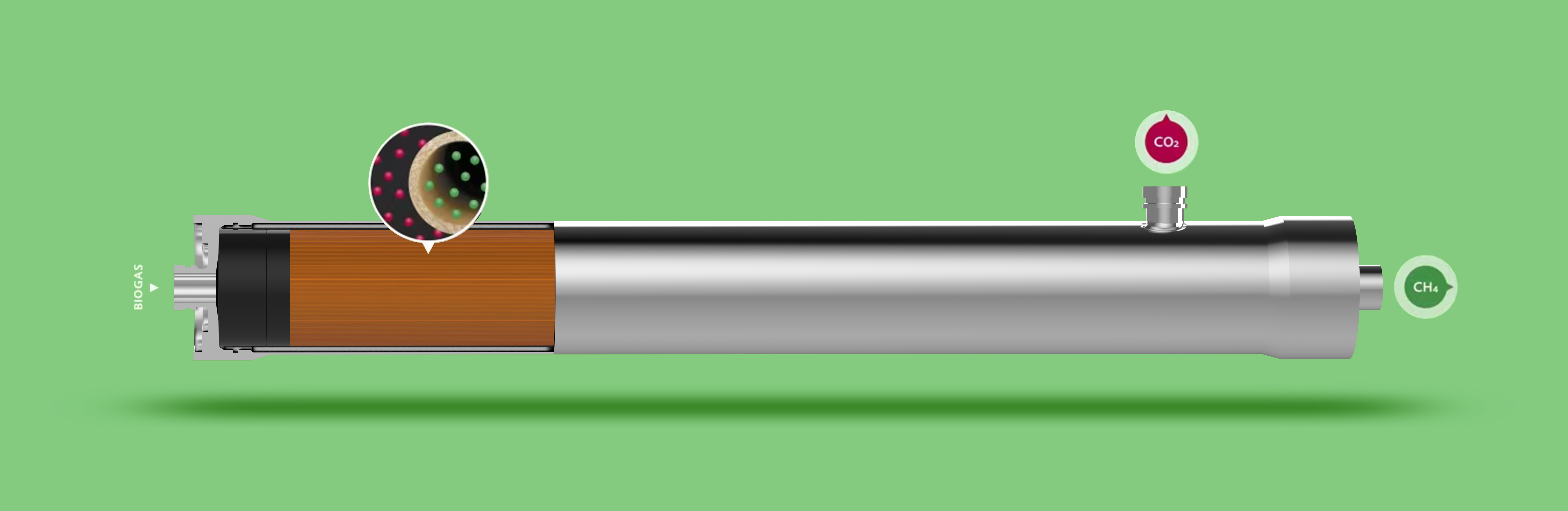

Jinlong gas separation membrane module